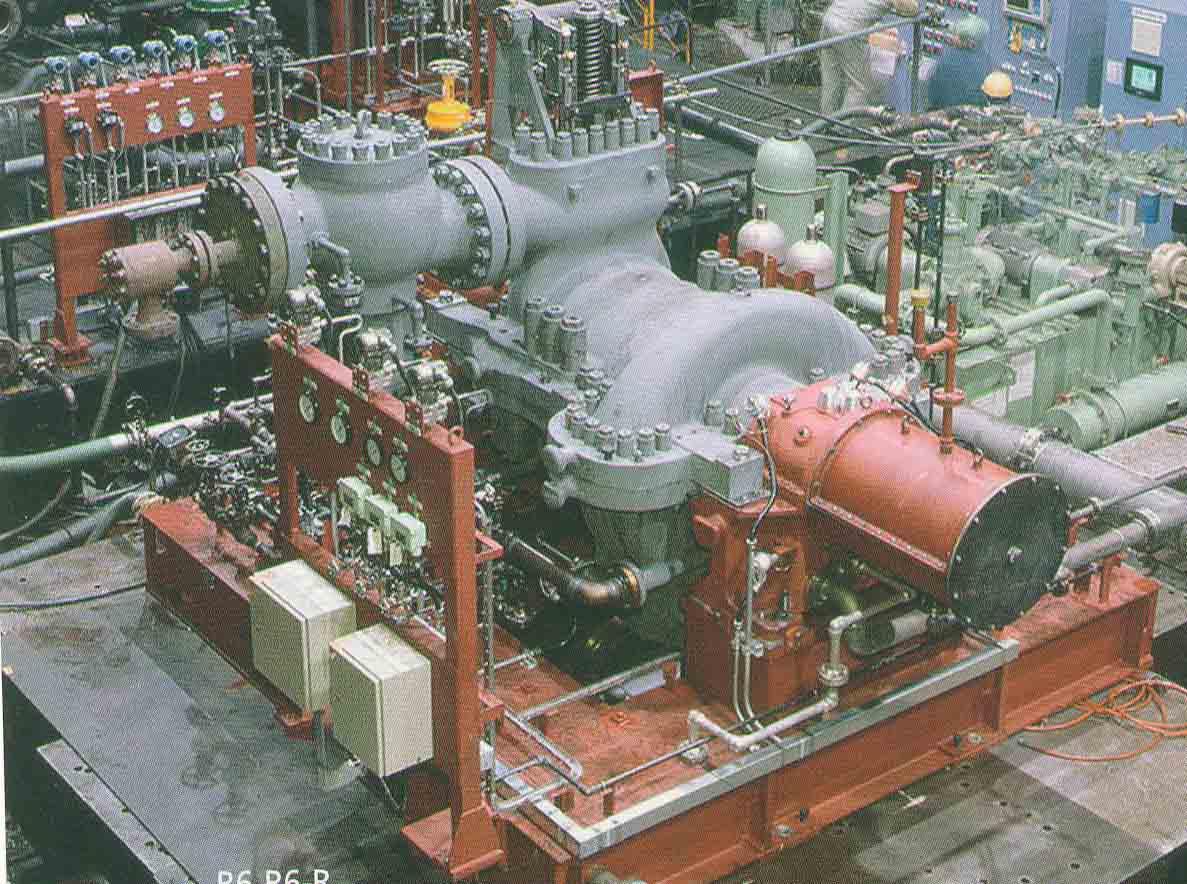

Back-pressure turbines utilize the pressure differential between inlet and outlet steam to efficiently convert a portion of the thermal energy of the steam into mechanical energy. The exhaust pressure is designed to be higher than the atmospheric pressure, so that the thermal energy of the exhaust steam can be reutilized in a variety of industrial processes. This series of products are known as ‘multistage’ steam turbines and are characterized by two or more rotor discs mounted on the shf. The number of stages and the average discs are optimized to suit output, revolutions, inlet steam pressure, temperature and exhaust pressure.

Model Information

- Model : B4, B5, B6, B8, B10

- Power Output : up to 50 MW

- Turbine speed : up to 14000 rpm

- Inlet pressure : up to 13 MPaG

- Inlet temperature : up to 550°C

- Exhaust pressure : up to 3.5 MPaG

- Exhaust nozzle : Down, upper or side exhaust

- Multiple extraction

- Controlled extraction : up to 2

- Geared drive to 1500 or 1800 rpm generator

- Baseplate under turbine for easy installation